We have provided below Listed real-time interview questions of UG NX (Unigraphics NX), which will greatly aid job seekers in thoroughly preparing for their interviews.

What is Unigraphics NX and how is it used in the product design and development process?

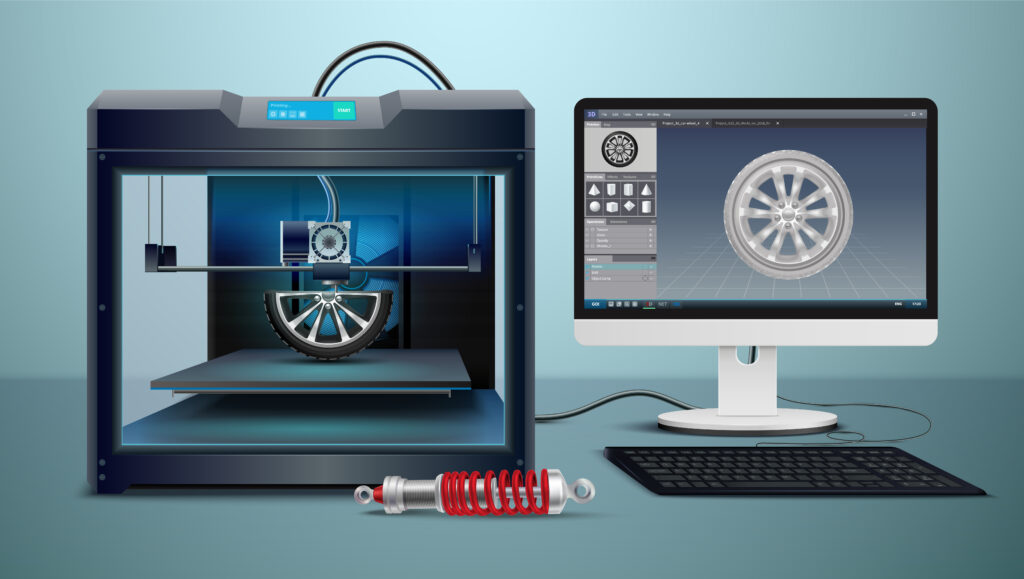

– Unigraphics NX, commonly referred to as NX, is a comprehensive software suite developed by Siemens Digital Industries Software. It is used in the product design and development process to create 3D models, perform simulations and analyses, generate manufacturing toolpaths, and manage data. NX enables engineers and designers to efficiently design and optimize products, validate their performance, and plan for manufacturing processes, resulting in reduced time-to-market and improved product quality.

What is Unigraphics NX and how is it used in the product design and development process?

– Creating a parametric model in Unigraphics NX involves defining the dimensions, relations, and constraints that control the geometry of the model. Here’s a general process:

Start with creating a 2D sketch or importing existing geometry.

Apply dimensions and constraints to the sketch, specifying sizes, distances, angles, etc.

Use sketch-based or feature-based operations to extrude, revolve, or manipulate the sketch into 3D geometry.

Establish relationships and constraints between features to maintain design intent and associativity.

Modify dimensions or constraints to drive changes throughout the model and maintain design updates.

How can Unigraphics NX be used for simulation and analysis?

– Unigraphics NX provides various tools for simulation and analysis, including structural, thermal, flow, and motion analyses. Engineers can define material properties, boundary conditions, and loads on the model to simulate real-world conditions. Unigraphics NX then performs calculations and provides results such as stress distribution, displacement, temperature, fluid flow patterns, and dynamic behavior. These results help assess the performance and behavior of the design, identify potential issues, and optimize the product for improved reliability and efficiency.

How does Unigraphics NX support collaboration and data management?

– Unigraphics NX offers features for collaboration and data management, facilitating efficient teamwork and ensuring data integrity. It provides capabilities for version control, secure storage, and sharing of design and manufacturing data. Engineers and designers can work simultaneously on the same project, managing changes and maintaining design consistency. Unigraphics NX also supports data exchange with other software platforms, enabling collaboration with external partners and suppliers.

Explain the difference between synchronous and ordered modeling in Unigraphics NX.

– In Unigraphics NX, synchronous modeling is a powerful method that allows designers to make direct edits to 3D geometry, regardless of its history or underlying feature tree. It provides flexibility and quick design modifications by focusing on the geometry itself rather than the feature history. On the other hand, ordered modeling follows a traditional feature-based approach, where design changes are made by editing the feature history tree and regenerating subsequent features. Ordered modeling provides more control over design intent and feature relationships.

What are some methods for creating and modifying complex surfaces in Unigraphics NX?

– Unigraphics NX offers several methods for creating and modifying complex surfaces, including:

Lofting: Creating a surface between multiple cross-sections or profiles to create smooth transitions.

Sweep: Creating a surface by sweeping a 2D profile along a path.

Boundary: Creating a surface by defining boundary curves or edges.

Patch: Creating a surface by filling gaps or blending between existing surfaces.

Freeform: Creating surfaces using sculpting tools, control points, or curves for more organic shapes.

How does Unigraphics NX facilitate collaboration with other CAD software?

– Unigraphics NX supports collaboration with other CAD software through its ability to import and export various file formats. It provides compatibility with industry-standard formats, allowing seamless exchange of design data with external partners and suppliers. Unigraphics NX also supports data translation and interoperability, ensuring that design data can be shared and utilized across different software platforms, promoting collaboration and integration within multi-CAD environments.

Explain the concept of sheet metal design in Unigraphics NX.

– Sheet metal design in Unigraphics NX involves creating and manipulating 3D models of sheet metal components. Unigraphics NX offers specialized tools and features to support sheet metal design, such as bend creation, flange creation, and unfold/fold operations. These tools allow designers to define parameters like material thickness, bend radius, and corner relief to accurately represent sheet metal behavior and create manufacturable designs.

How does Unigraphics NX support data exchange and collaboration with other software applications?

– Unigraphics NX supports data exchange and collaboration through various methods:

Import and export of industry-standard file formats, such as STEP, IGES, and STL, ensuring compatibility with other CAD and analysis software.

Integration with PLM (Product Lifecycle Management) systems to facilitate data management, revision control, and collaboration across teams and organizations.

Application programming interfaces (APIs) and customization options to enable seamless integration with other software applications, enabling streamlined data transfer and interoperability.